- Inicio

- 3D Printers and accessoires

- Moldes y Réplicas

- Siliconas de Estaño

- Siliconas de Platino

- Gomas de Poliuretano

- Alginato

- resinas de Poliuretano

- Espuma de Poliuretano

- Epoxi

- Látex

- Mask Making Latex

- Mold Making Latex

- FormX Elastica

- Monster Makers Kit de Espuma de Látex

- Monstermakers Mask making latex RD-407

- Monstermakers additives & Components

- Holden's HX-200™ Coating/Dipping Latex

- Holden's Brushable HX- Body Latex™

- Holden's Mold Making Latex HX-80™

- Holden's Mold Making Latex High Viscosity HX-974™

- Holden's Mask Making Latex - Pourable HX-407™

- Holden's Mask Making Latex - Brushable HX-807™

- Holden's Cosmetic Latex™

- Holden's Frisket Mask Latex

- Holden's HX-Injection Medium™

- Latex Accessories

- Latex Pigments

- Latex Paint

- Latex Thickener

- Yeso y Hormigón

- Poliester

- AcrylCast

- Fundición Prince August

- Modelar

- Jesmonite sistema acrílico

- Buddy Rhodes Sistema de Hormigón

- Sellar y Despegar

- Pigmentos

- Jesmonite Pigments

- Pure Pigments

- Ultra Fine Pigments

- Silc Pig™ pigmentos

- Glow Worm™ Pigmentos

- Cryptolyte™

- Silc Pig™ Eléctrico

- SilTone

- SilTone Kits

- FuseFX pigmentos de silicone

- Silicone Coloring System S.A.M

- Key-Pigments Silicone Pigments

- Flock fibras

- Latex Pigments

- Polyester Pigmentos

- UVO Pigmentos resistentes al UV

- Tintes SO-Strong™

- Tintes Ignite™

- Real Metal Powders

- Faux Metal Powders

- Cast Magic™ Polvos

- Pinturas

- Rellenos & Refinamiento

- Aditivos

- Disolventes y diluyentes

- Adhesivos

- Herramientas

- Equipos

- Maquillaje

- máscara de goma pintura de grasa

- Skin Illustrator Paletas

- Skin Illustrator líquido

- Fleshtone 60ml

- Fleshtone 120ml

- Dark Fleshtone 60ml

- Dark Fleshtone 120ml

- FX 60ml

- FX 120ml

- FX 240ml

- Complexion 60ml

- Complexion 120ml

- Alchemy 60ml

- Alchemy 120ml

- Grunge 60ml

- Grunge 120ml

- Grunge 240ml

- Mardi Gras 60ml

- Mardi Gras 120ml

- Necromania 60ml

- Mekash Colors 60ml

- Clear Gloss 60ml & 120ml

- Glo-Worm 60ml & 120ml

- Tattoo Classic 60ml & 120ml

- Sunburn

- Alphabetical all

- Skin Illustrator Individual

- Skin Illustrator Glazing Gels

- Skin Illustrator Concentrates

- Skin Illustrator Glazing Spray

- Skin Illustrator Mouth FX

- Allied FX (Blue Bird)

- RipperFX Palettes

- Stacolor Paletas de Maquillaje

- PAX - Pinturas Thom Suprenant

- Tattoo

- MaqPro Farde Palettes

- MaqPro Make-Up Mixer

- MaqPro Creamy

- Pinceles Maquillaje

- MaqPro Bruise Gel

- Old Age Stipple

- Sponges and Applicators

- Stamps & Molds

- Head Armatures

- FormX Tools

- Kryolan maquillaje

- efectos especiales

- material protésico

- Ayuda para elegir

- FormX Academy

- Marcas

- Literature

Compat ™ 45

Buy Smooth-On at FormX

Smooth-On es uno de los principales fabricantes mundiales de materiales de modelado 3D, como materiales para la fabricación de moldes, fundición y efectos especiales, pero también resinas, adhesivos y equipos de fundición industrial. FormX es el principal distribuidor de productos Smooth-On en toda Europa.

El uretano Compat ™ 45 es un caucho de uretano único que no inhibirá el curado de la mayoría de los cauchos de silicona Smooth-On platinum o de estaño. Presenta una baja viscosidad para una fácil mezcla y vertido y cura con un mínimo atrapamiento de burbujas. La relación de mezcla es 1A: 1B en volumen (85A: 100B en peso), la vida útil es de 25 minutos y el caucho se cura con una dureza Shore definitiva de Shore 45A. El caucho curado es dimensionalmente estable (baja contracción), ofrece buena resistencia al desgaste y excelente vida útil de la biblioteca. Compat ™ 45 se puede usar para una variedad de aplicaciones, incluyendo la fabricación de moldes para moldear partes del cuerpo de silicona, pieles animatrónicas y entrenadores médicos, así como para hacer maestros de goma que se pueden moldear con platino o silicona de estaño sin problemas de inhibición.

Importante; No utilice Ecoflex ™ Gel, Ecoflex ™ 00-10, Encapso-K, Rubber Glass ™, Solaris ™ u Sorta-Clear ™ 12 o 37 con este producto. No son compatibles y se producirá inhibición.

Compat ™ 45

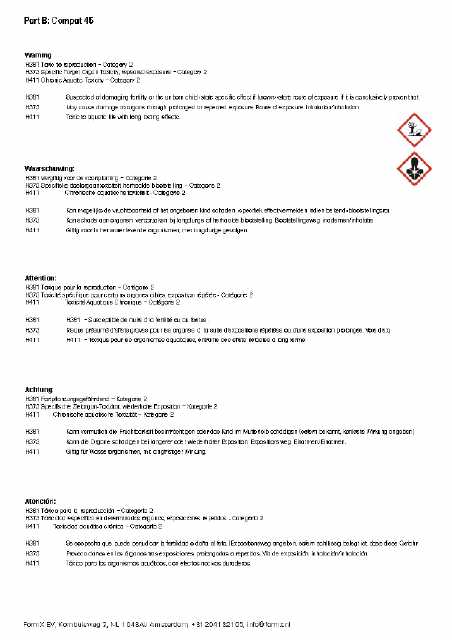

Compat 45 Safety Information

START BY PREPARING YOUR MODEL...

Preparation - Store and use at room temperature 23°C. These products have a limited shelf life and should be used as soon as possible. Use in a low humidity environment (below 50% RH). Mixing containers should have straight sides and a flat bottom. Mixing sticks should be flat and stiff with defined edges for scraping the sides and bottom of your mixing container. Good ventilation (room size) is essential. Wear safety glasses, long sleeves and rubber gloves to minimize contamination risk.

Some Materials Must Be Sealed - Models with porous surfaces (gypsum plasters, concrete, wood, stone, etc.) must be sealed prior to applying a release agent. Sonite™ Wax (available from FormX) is a proven sealer for porous surfaces.

IMPORTANT - Ecoflex Gel does not cure against Compat™ 45. We do not recommend making a gel filled makeup prosthetic appliance in Compat™ 45, as cap plastic material will adhere to Compat™ 45

Non-Porous Surfaces - Metal, glass, hard plastics, sulfur free clays, etc. require only a release agent.

Applying a Release Agent - Use a release agent made specifically for mold making.

IMPORTANT: If casting platinum silicone into Compat™ 45, only use Ease Release 200 when making your mold, DO NOT use Universal Mold Release.

A liberal coat of release agent should be applied onto all surfaces that will contact the rubber.

IMPORTANT: To ensure thorough coverage, lightly brush the release agent with a soft brush over all surfaces of the model. Follow with a light mist coating and let the release agent dry for 30 minutes. Because no two applications are quite the same, a small test application to determine suitability for your project is recommended if performance of this material is in question.

MEASURING & MIXING...

Liquid urethanes are moisture sensitive and will absorb atmospheric moisture. Mixing tools and containers should be clean and made of metal or plastic. Materials should be stored and used in a warm environment 23°C.

IMPORTANT: Pre Mix the Part B before using. After dispensing equal amounts of Parts A and B by volume into mixing container, mix thoroughly for at least 3 minutes making sure that you scrape the sides and bottom of the mixing container several times.

After mixing parts A and B, vacuum degassing is recommended to eliminate any entrapped air in Compat™ 45. Vacuum material for 2-3 minutes (29 inches of mercury), making sure that you leave enough room in container for product expansion.

If Mixing Large Quantities 7 kgs. or more at one time, use a mechanical mixer (i.e. Squirrel Mixer or equal) for 3 minutes followed by careful hand mixing for one minute as directed above. Then, pour entire quantity into a new, clean mixing container and do it all over again.

POURING, CURING & PERFORMANCE... For best results, pour your mixture in a single spot at the lowest point of the containment field. Let the rubber seek its level up and over the model. A uniform flow will help minimize entrapped air. The liquid rubber should level off at least 1.3 cm over the highest point of the model surface.

Curing - Allow rubber to cure a minimum of 24 hours at room temperature 23°C before using. Cure time can be reduced with mild heat. Do not cure rubber where temperature is less than 18°C.

Thickening Compat™ 45 for Brush On Applications - To thicken Compat™ 45 for brush on applications, only use URE-FIL™ 11 filler. Recommended starting proportion: Mix 1 part URE-FIL™ 11 with 1A:1B of Compat™ 45. Add more in small amounts if necessary. DO NOT USE URE-FIL™ 9 (CAB-O-SIL) WITH COMPAT™ 45.

IMPORTANT - Do not add Kick-iT!™ cure accelerator to Compat™ 45, this will cause cured urethane to inhibit silicone.

Post Curing - Optional . . . Following a 24 hour cure, heating the rubber to 65°C for 4 to 8 hours will increase physical properties and performance.

Using The Mold - If using as a mold material, a release agent should be applied to the mold before each casting. The type of release agent to use depends on the material being cast. The proper release agent for wax, liquid rubber or thermosetting materials (i.e. Smooth-On liquid plastics) is a spray release made specifically for mold making available from Form X Prior to casting gypsum plaster materials, sponge the mold with a soap solution for better plaster flow and easy release. Aquacon™ Water Based Release Agent available from Form X is recommended for releasing abrasive materials like concrete.

Performance & Storage - Fully cured rubber is tough, durable and will perform if properly used and stored. Molds should be stored on a level surface at room temperature in a dry environment. Do not stack molds, expose them to moisture or UV light for prolonged periods.

IMPORTANT: Shelf life of product is reduced after opening. Remaining product should be used as soon as possible. Immediately replacing the lids on both containers after dispensing product will help prolong the shelf life of the unused product. XTEND-IT™ Dry Gas Blanket available from Form X will significantly prolong the shelf life of unused liquid urethane products

Ayuda para elegir

Todos nuestros productos enumerados por aplicaciones: "Lifecasting", Escultura, Moldes, Fundición, Maquillaje FX, Réplicas, Dientes y Kits de aprendizaje.

su ventanilla única para materiales de modelado en 3D